As a leading global supply chain and e-commerce service provider, Arvato needed a cutting-edge automation solution to enhance efficiency, reduce costs, and scale seamlessly with growing order volumes. With complex logistics operations and high customer expectations, the company sought a partner that could integrate advanced robotics into their existing infrastructure without disrupting workflows.

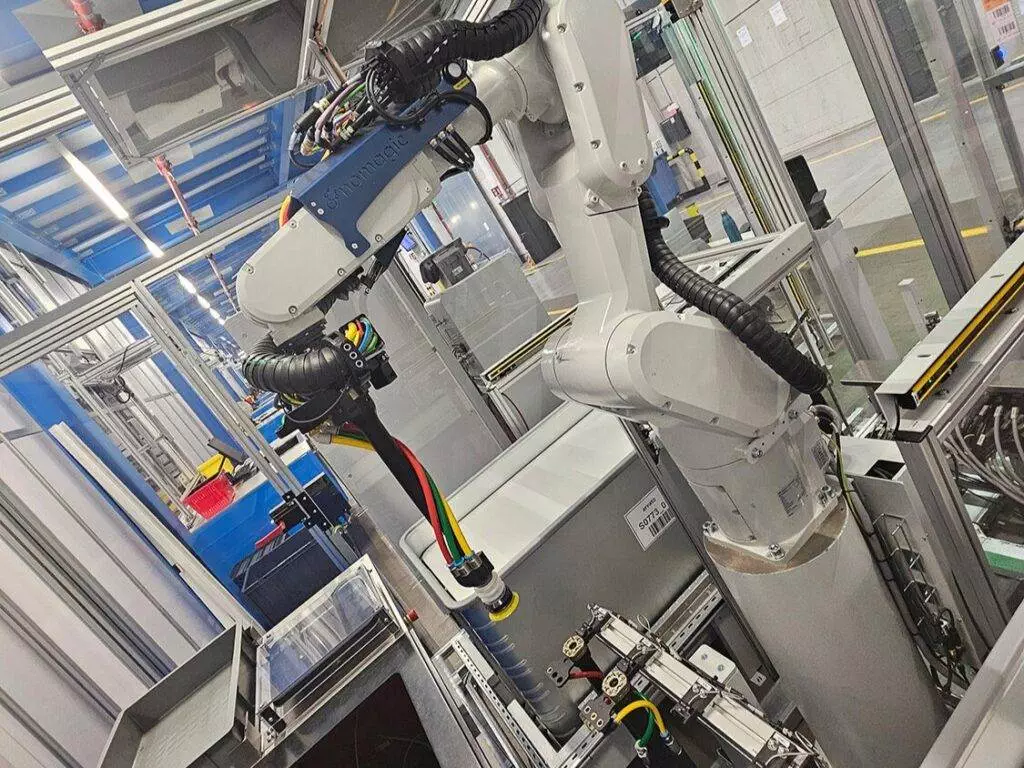

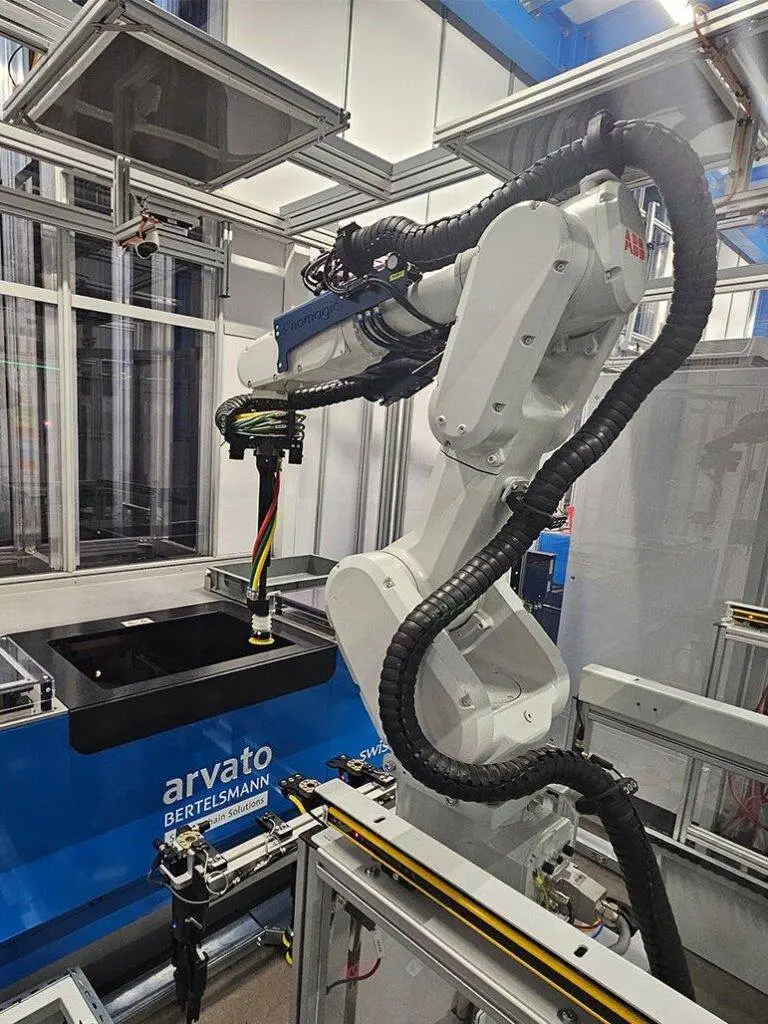

Nomagic delivered a tailored AI-powered picking solution that streamlined fulfilment processes, increased picking accuracy, and optimised operational flow. By combining intelligent automation with Arvato’s extensive logistics expertise, the partnership unlocked new levels of efficiency, ensuring a fast, flexible, and future-proof warehouse operation.

To optimize the picking process, the returned items (e.g. T-shirts) need to be grouped by different colors - Robots autonomously choose the right grouping using their vision system.

The robot is scanning each return to make sure there’s no double picks and to support accurate inventory management, all this on the fly, without losing time.

To maximise storage density, foiled fashion items are often placed vertically into small compartments, posing a challenge during picking - Nomagic has deployed its latest tool, a finger gripper, to solve this challenge.

We truly have established a second-to-none-system that just cannot be found elsewhere.

Nomagic has used laser curtains instead of doors for trolley exchange, which makes the process easier today and, above all, makes the station ready for future AGV deployment.

Thanks to the many years of experience handling fashion at other customers’ warehouses, Nomagic has been able to instantly start working with the assortment at Arvato.

Get in touch with Nomagic to see how our innovative technology can take your fulfillment processes to the next level.