Fiege, a leader in logistics and supply chain management, faced the growing challenge of meeting rising e-commerce demands while maintaining speed, accuracy, and efficiency in its fulfilment centres. To stay ahead, Fiege partnered with Nomagic to integrate intelligent robotics into its operations, automating repetitive picking tasks and optimising warehouse workflows.

By leveraging Nomagic’s AI-driven robotic picking solutions, Fiege achieved greater precision, reduced operational costs, and improved throughput—all without disrupting existing infrastructure. This case study explores how Fiege successfully scaled automation, enhanced worker productivity, and set a new benchmark for warehouse efficiency with the power of smart robotics.

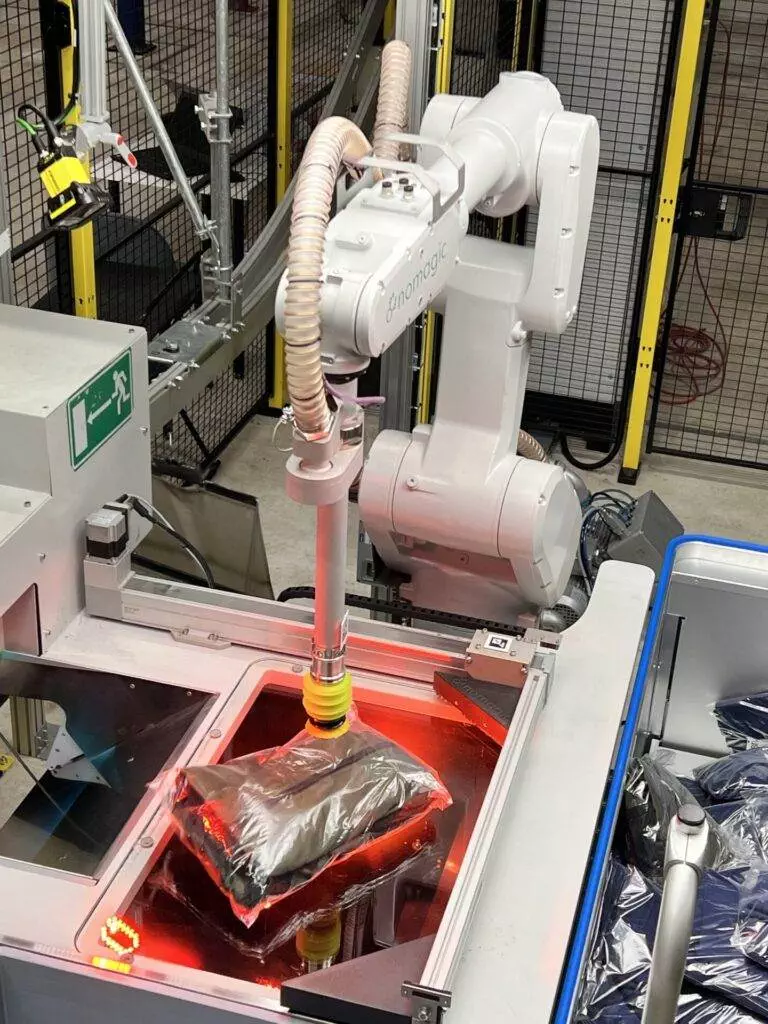

A proportion of items are not packed in polybags. Grasping cloth using suction is unreliable - the item has to be picked by the banderole, which is a new challenge for the picking function.

For a human, rotating items to reveal a barcode is straightforward. However, in order to automate this process at a high throughput and success rate, one needs to introduce operational adjustments and maximise the effectiveness of scanning even with limited barcode visibility.

A batch picking use case covering a challenging itemset consisting of a variety of DIY items such as heavy tool kits, which need to be placed quickly and efficiently within the target trolley.

Fiege uses existing cardboard compartments to divide bins for efficiency. Bins may be divided into 2, 4 or 6 compartments, with multiple orientations and materials used to split them. Such variety requires strong AI & vision capabilities and careful and precise maneuvering.

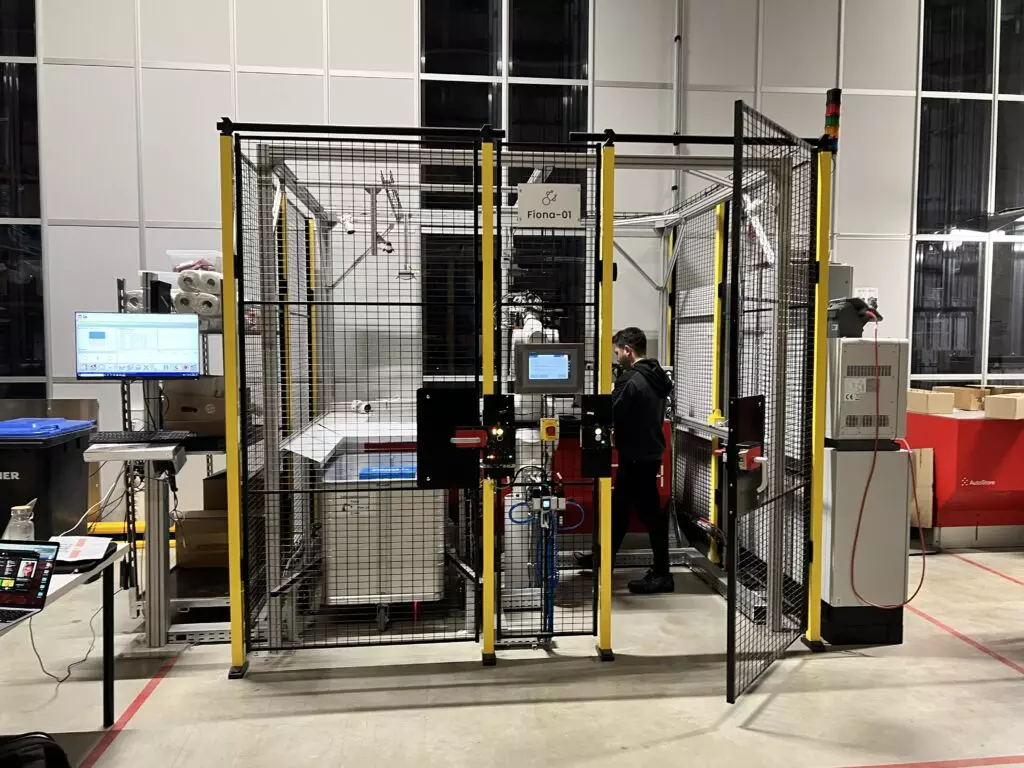

Nomagic delivered tailored solutions for AutoStore picking and Pocket Sorter induct, working closely with our team to solve our specific challenge.

Nomagic provided the flexibility in implementation required by Fiege. For example, Nomagic’s justInduct Robot required no integration effort on the Warehouse Control System side.

In terms of hardware, the justPick robots were adapted to use spring floor trolleys, seamlessly integrating the use case within the flow of manual operation.

Nomagic supported the optimised use case (batch picking) with existing equipment at the Fiege site to transfer goods outside the Automated Storage & Retrieval System (trolleys) and within it (cardboard dividers)

Pocket sorter induction is among the most repetitive types of tasks in a modern warehouse. By automating it, Fiege can move its operators to tasks where they can use their skills better, improving efficiency and employee satisfaction.

Nomagic has shown its capability to deliver two different solutions for two distant kinds of assortments. The AI and robotics capabilities of Nomagic as well as its customer centricity have allowed it to create a broad partnership that Fiege is looking to expand.

Using the Nomagic’s Robot-as-a-Service model based on hardware leasing, Fiege had no CAPEX, which significantly shortens their Return on Investment period.

Get in touch with Nomagic to see how our innovative technology can take your fulfillment processes to the next level.