The fashion industry, long driven by seasonal cycles and consumer demand for the latest styles, has evolved more in recent years than ever before, partially in reaction to different crises:

The accumulation of these crises has created planning nightmares for supply chain professionals, with volume forecasts that are hard to trust and logistical challenges specific to each crisis.

The big names in Fashion are constantly evolving to meet the demands of a similarly changing world.

Just as the industry is evolving to meet the demands of operation, doing so is a fine balance between:

How to balance and combine these conflicting goals is a key challenge for the intralogistics professionals in the fashion industry.

The end of COVID-19 reduced e-commerce volumes close to what they were pre-pandemic. The new post-COVID world of an e-commerce based utopia which a lot of us imagined, did not emerge. What did emerge for fashion retailers was lower volumes, greater competition and a very real pressure on costs.

Intralogistics professionals are still actively looking for opportunities to reduce fulfillment costs per item, three years later. In times of overall inflation and labor fluctuation in Europe, this means looking for ways to reduce their dependency on hard to find labour for key fulfillment operations, doing the most repetitive tasks.

“Zero touch fulfillment” has become a key target for the most advanced leaders in the industry. In this paradigm, products go from storage to the customer package autonomously, without any human operator touching the product. The first e-commerce operation to reach this goal could gain significant cost and margin advantage over its competition, enabling 24/7 seamless fulfillment at a predictable cost.

Another key driver of costs is returns. Return rates in fashion often exceed 30 per cent, with very complex and time consuming processing for every returned item. Beyond measures to reduce this level of returns, designing efficient returns processing and resale ready refurbishing workflows becomes essential. In a recent Market study, Interact Analysis categorized Returns as one of the “6 major opportunities for automation vendors between 2025 and 2030”.

The introduction of AI-powered Robotics has therefore become a key topic in order to both achieve “zero-touch fulfillment” but also to maximize automation across the entire returns processes. The flexibility offered by AI-powered robots will be key to address a wide variety of applications, filling the gaps toward end-to-end automation.

Consumers expect the latest trends to be available in stores or online within days of their debut, compelling brands to compress design-to-delivery timelines. Fast fashion pioneers like Zara and H&M in their stores and Zalando, ASOS and Otto in e-commerce have set new standards in this highly competitive arena by consistently developing their fulfillment capabilities and infrastructure.

The most advanced distribution centers become fulfillment powerhouses designed to retrieve the required products within a massive set of SKUs and assemble them into an order that is ready for shipping within 24h, enabling same day delivery.

In such a distribution center, the average SKU count is higher than what most industries would expect, with a typical Fashion distributor housing over 1 million different SKUs with variations in size, colour and style. Order profiles can vary dramatically, requiring sophisticated warehouse management systems (WMS) and complex labour planning.

Automating as much of this workflow as possible is a necessity with Mini-Load, Shuttles, Conveyors, Pocket Sorters and other automation sortation systems forming the backbone of the modern warehouse. By handling the complexity of connecting those different automation systems, AI driven Robotics is solving what was previously a bottleneck for many distribution and storage centres.

Learn about how AI is driving the evolution of the warehouse here

On top of customers expecting lower costs and faster delivery times, a growing segment of customers will expect fulfillment practice that matches their sustainability standards. Package types and materials have then to adapt to customer preferences, further complexifying the equation fashion intralogistics professionals need to solve.

A hot topic for fashion is the use of plastic packaging. Traditionally, garments are transported in polybags and a large portion of orders are assembled into a shipping plastic sleeve. Customer preference but also regulation limiting the use of single use plastics, force supply chains to adapt, find new materials or even remove some layer of protective packaging. This means automation needs to be able to work with different packaging types.

Ensuring that conveyors, sorters, but also picking robotic arms have the flexibility to handle non-plastic packaging or lack of packaging becomes an important criteria when introducing new automation technology.

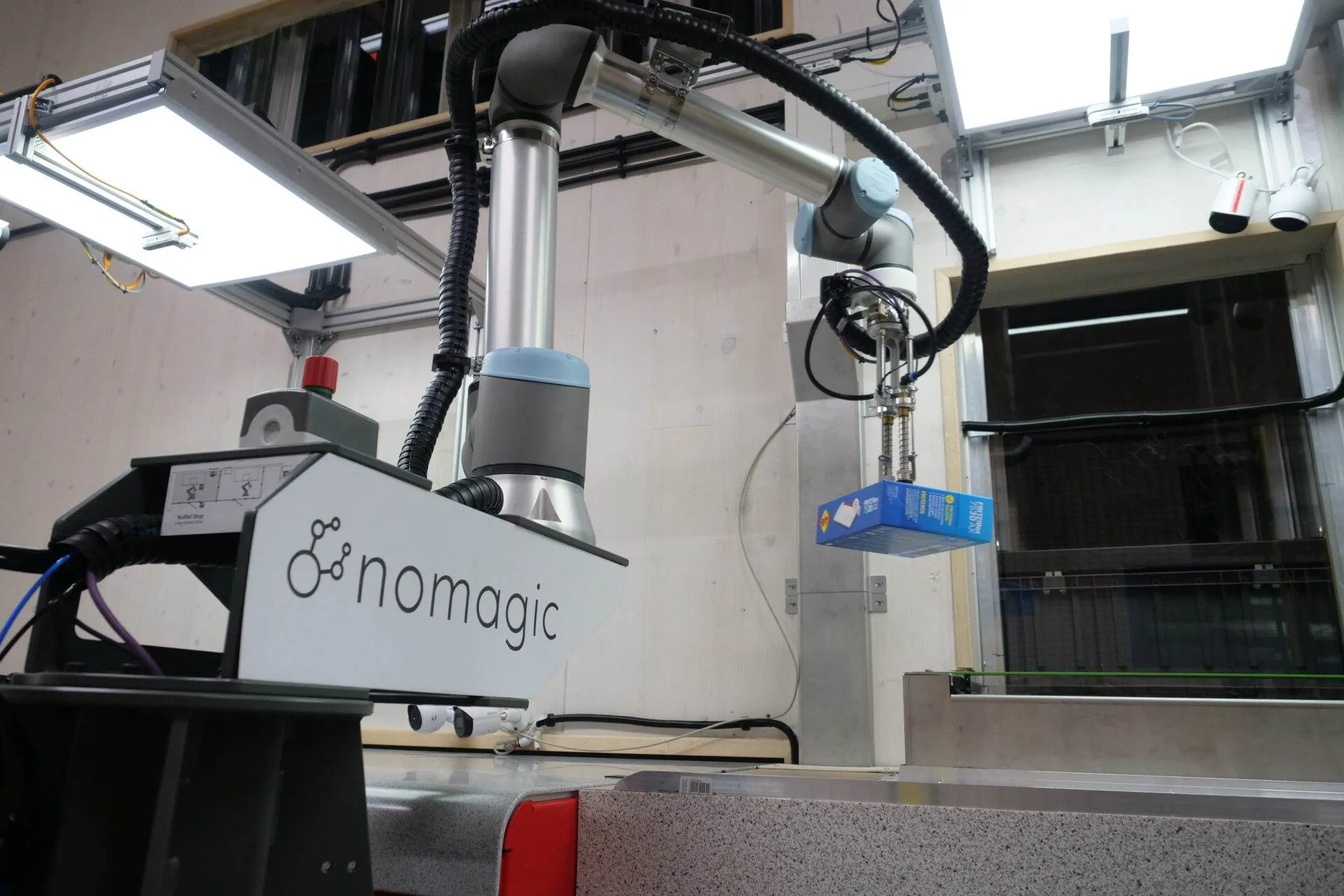

This has pushed Nomagic to invest significantly in a tool changer and proprietary grippers for its AI-powered robots, which provides the required flexibility in handling all types of packaging.

Another unique logistical consideration in fashion, especially for sports and footwear brands, is shoe packaging. The shoebox conundrum seems like one of those things that is fairly consistent in size, packaging and design. While this is the case for the first two points, the design bit is where it gets tricky.

Shoeboxes are not sealed, they are designed to be opened easily and eagerly by the end user. This presents huge challenges in the automation of fashion focused fulfillment centres but also presents a huge opportunity to solve a persistent problem. Picking shoe boxes is one area where AI-powered robotics may be able to help. Around twenty percent of fashion shipments are shoes, creating a robotic solution to this challenge will offer a critical step towards the ‘lights out warehouse’.

Learn more about Nomagic’s robotic fleet here

The logistics of fast fashion is a high stakes, high speed environment that challenges even the most sophisticated players. As brands pursue ambitious targets for speed, sustainability and cost, they must adapt to a landscape shaped by ecommerce growth, shifting consumer expectations and global disruptors. Industry leaders like ASOS, Zalando, OTTO, Inditex (Zara) and H&M are setting the pace and are redefining what is possible.

In this fast moving sector, the only constant is change. To stay competitive, fashion brands and logistics providers alike must embrace continuous innovation, invest in technology and keep a sharp eye on both global trends and local execution.

The future of leading fashion warehouses will be defined by their ability to integrate intelligent automation. AI-Robotics will be a key piece of the puzzle to address conflicting priorities faced by intralogistics professionals to reduce costs, increase speed and guarantee sustainable practicesBrands that successfully leverage these tools while maintaining agility will be best positioned to navigate the dual pressures of fast fashion and sustainable practice.

Free consultancy with Nomagic experts on how to leverage AI powered robots

Get in touch with Nomagic to see how our innovative technology can take your fulfillment processes to the next level.